🧩 3D Printing Material Guide: Choosing the Right Material for Your Project

- JL Pflash

- 2 days ago

- 3 min read

By Oxwave Technologies

🚀 Introduction: Material Matters in 3D Printing

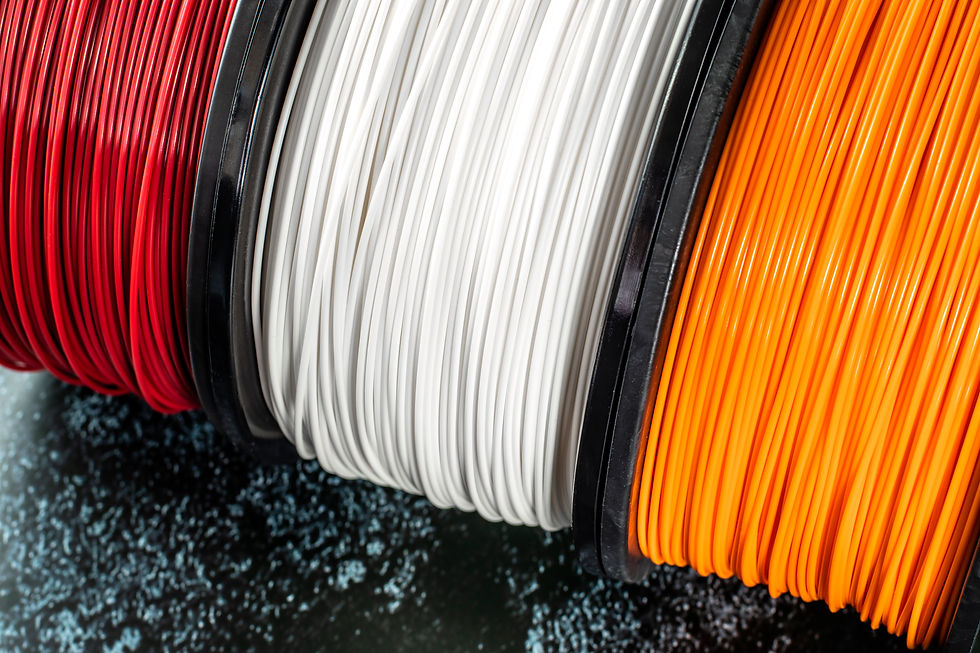

In the world of additive manufacturing, choosing the right 3D printing material is crucial for achieving the perfect balance of strength, flexibility, and finish. At Oxwave Technologies, we provide professional 3D printing services tailored to your application — from medical and industrial prototypes to functional production parts.

Whether you’re developing a concept or manufacturing end-use components, understanding material properties helps you unlock the full potential of 3D printing technology.

🌱 1. PLA (Polylactic Acid) – Easy, Sustainable, and Reliable

PLA is the go-to material for beginners and rapid prototyping. Made from renewable resources like corn starch, it’s biodegradable and easy to print, with excellent dimensional accuracy and surface finish.

Best for: Visual models, display pieces, educational prototypesPros: Easy to print, affordable, environmentally friendlyCons: Brittle, low heat resistance

✅ Ideal for low-cost, high-accuracy projects where appearance matters more than strength.

🔧 2. ABS (Acrylonitrile Butadiene Styrene) – Strong and Functional

ABS is a durable thermoplastic used for engineering and industrial applications. It’s known for impact resistance and temperature stability, making it perfect for functional prototypes, enclosures, and automotive parts.

Best for: Mechanical components, tooling, enclosuresPros: Strong, durable, heat-resistantCons: Requires heated bed, emits fumes during printing

✅ Choose ABS for durable parts that must handle real-world wear and stress.

🧪 3. PETG (Polyethylene Terephthalate Glycol) – Durable and Versatile

PETG offers the strength of ABS with the printability of PLA. It’s resistant to moisture, chemicals, and impact, making it an ideal material for food-safe applications and functional prototypes.

Best for: Containers, fixtures, and outdoor componentsPros: Tough, flexible, minimal warpingCons: Prone to stringing if not tuned properly

✅ Perfect for products that need both flexibility and durability.

⚙️ 4. Nylon – Industrial-Grade Strength and Flexibility

Nylon is a high-performance material used in engineering and industrial applications. It offers outstanding wear resistance, flexibility, and mechanical strength.

Best for: Gears, hinges, load-bearing partsPros: Strong, flexible, abrasion-resistantCons: Hygroscopic (absorbs moisture), requires high print temperature

✅ Excellent for long-lasting functional components and assemblies.

🌀 5. TPU (Thermoplastic Polyurethane) – Flexible and Resilient

TPU combines flexibility and toughness, producing rubber-like parts that can bend, stretch, and absorb impact.

Best for: Seals, gaskets, grips, wearable devicesPros: Elastic, shock-resistant, durableCons: Slower print speeds, requires precise calibration

✅ Use TPU for flexible prototypes and protective components.

💎 6. Resin – Precision for High-Detail Applications

Resin printing (SLA/DLP) provides unmatched surface finish and detail. It’s ideal for applications that demand micron-level precision — from dental models to jewelry prototypes.

Best for: Miniatures, dental models, high-precision prototypesPros: Smooth finish, detailed, professional-gradeCons: Requires post-curing and handling care

✅ Choose resin for premium, ultra-detailed parts.

🏁 Oxwave Technologies: Your Partner in Precision 3D Printing

At Oxwave Technologies, we deliver industrial-quality 3D printing services that combine advanced materials, cutting-edge equipment, and decades of engineering experience.

We’re known for our:

Competitive pricing without compromising quality

Unbeatable lead times on every order

Expert material guidance for optimal results

Custom finishing and post-processing services

From rapid prototyping to end-use production, we help you bring your ideas to life — with accuracy, speed, and reliability.

🧠 Final Thoughts: The Right Material Defines Success

Each 3D printing material brings its own unique strengths. Whether you need lightweight plastic prototypes, durable mechanical parts, or biocompatible components, Oxwave Technologies provides the expertise and precision you can count on.

From concept to creation, we turn layers into innovation.

📞 Ready to Start Your Next 3D Printing Project?

Contact Oxwave Technologies today for expert guidance on material selection and 3D printing solutions that meet your performance, cost, and time requirements.

Comments